Lego Builder

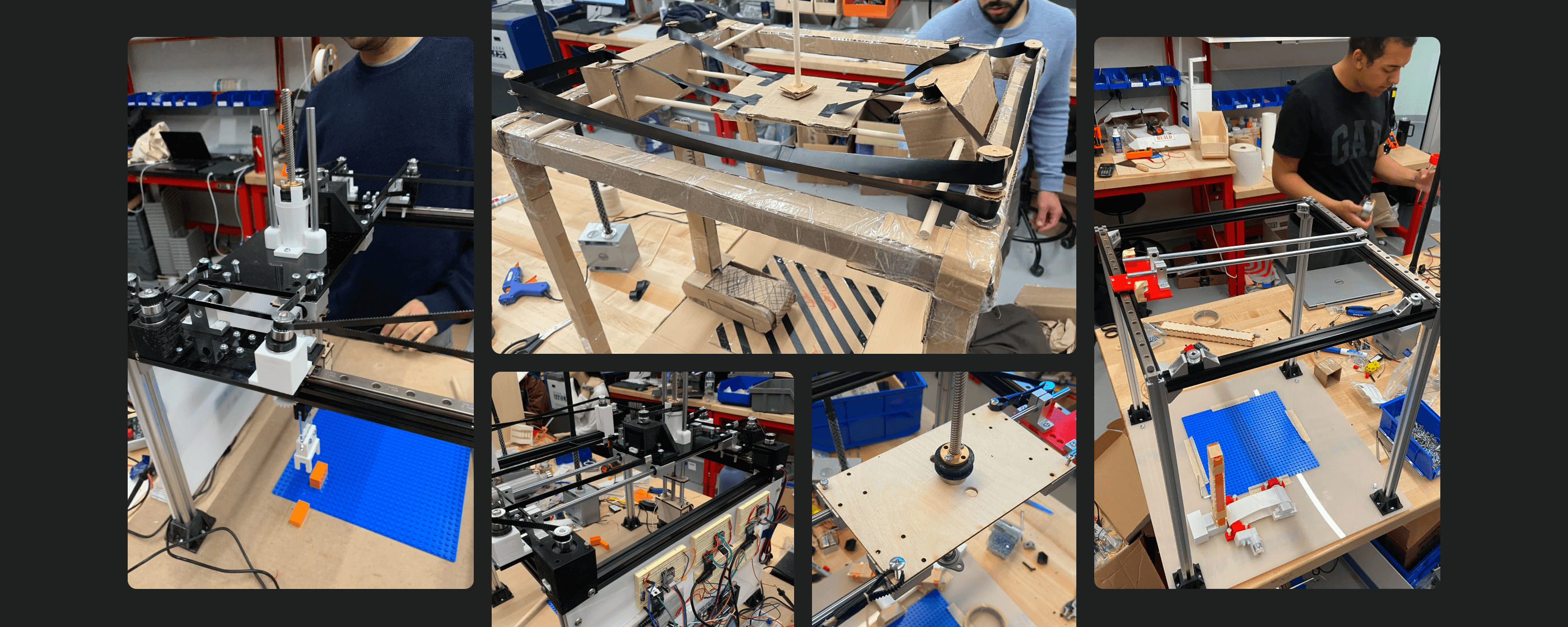

Building a 3D Printer, but with Lego Blocks

Often overlooked, construction can be a monumental task. People live in buildings every day that take months to years of hard work to create without a second thought about all the specially trained building crews and heavy machinery. Were the process to be moved to robots then a great deal of the construction practice could be expedited. Our idea is to create a robot on a much smaller scale that takes legos from a lego brick reservoir and positions them down, on a lego base plate, to create a structure from the given instructions. The bricklayer robot would be roughly the size of an Ultimaker and would be able to sort lego bricks and orient them for placement. This project represents a proof of concept to automate the construction of buildings and ultimately construct buildings free of human error and in a much quicker timeline.

Initial Design Overview

The overall idea is to create a robot that takes lego bricks from a reservoir and places them down to create a structure from the given instructions. We plan to pre-write the code based on the building instructions. The main building site (where the lego structure gets created) is going to be within a 3-dimensional space with a 32*32 plastic square lego base plate. We are restricting the lego bricks to single colored 2*4 pieces.

As the input of the system, we would pre-sort an open “magazine” structure with a pile of loose lego pieces and a belt at the bottom to transfer one single piece out to a designated “pick up zone”.

To pick up the lego brick from the “pick-up zone,” we would design a moveable lego picker with an extendable claw end that moves two-dimensionally with a belt and rail structure at the top (coreXY) and vertically with a motorized rack and pinion. To pick up the lego brick, there will be a claw at the end of the pick-up point with rubber material to increase friction. The claw would be open to start by utilizing a spring and would be closed by cable, which is controlled at the top of the Placement Unit (PU).

After the claw picks up a piece, it would move to the exact X, Y position then push the lego into the structure it is building through the weight of the crane and the solenoid. . Once the piece is attached, we release the claw and move the lego picker back to the pick-up zone.

Special thanks to: Xinda Ma & Julian.